Additional Equipment

Additional Equipment

To ensure a smooth operation of your recycling plant, a lot of different recycling machinery is needed before, after, or in between the main machines. Here you will find several reliable recycling machines suitable for intermediate storage, feeding, cleaning, cutting, and more.

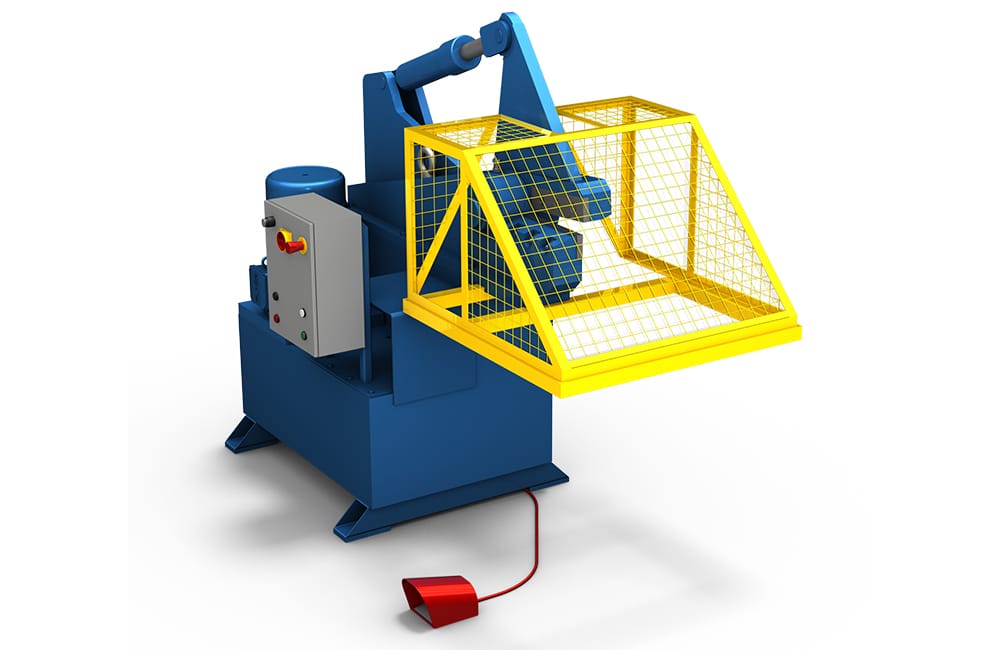

ACSR Cable Shear

If processing ACSR cable or similar type of cable, the ACSR Shear (M16) is safe and efficient recycling machinery for reducing long cable lengths in seconds. It is simple to load, operate, and maintain. The ACSR Shear M16 offers a very useful and economic way of preparing solid cables for granulation.

The principle of operation of the shear is a flying knife and a static knife. During every revolution the flying knife passes the static knife and cuts through any cable that overhangs the static knife. The flying knife operates at a constant speed of 400 rpm, which means that the speed of the cutting measured in meters per minute is determined by the feed rate of the cable through the hydraulic feed rollers.

The ACSR Cable Shear is available with both hydraulic motor (M16-2) and electric motor (M16-5) depending on your requirements.

The ACSR Cable Shear is suitable for

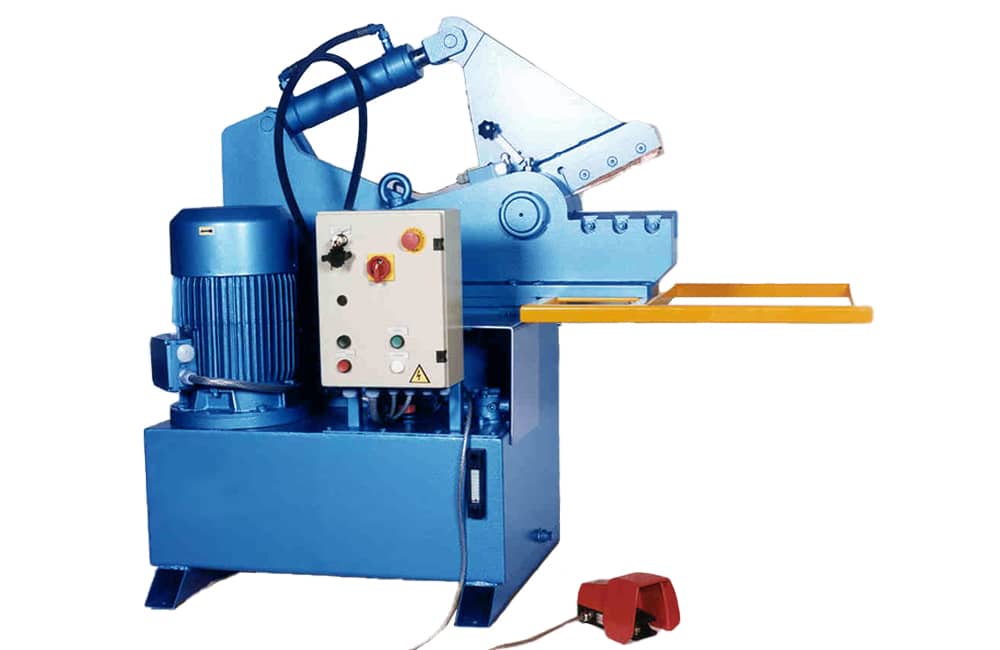

Alligator Shear

The ELDAN Alligator Shear is a heavy-duty hydraulic metal and cable shear with a cutting power of 40 tonnes. The machine is operated by a foot pedal for easy operation and with adjustable gap opening to optimize cutting. A powerful recycling machines for reducing cables, rods, bars, coils, bundles, etc. prior to recycling.

The Alligator Shear is suitable for

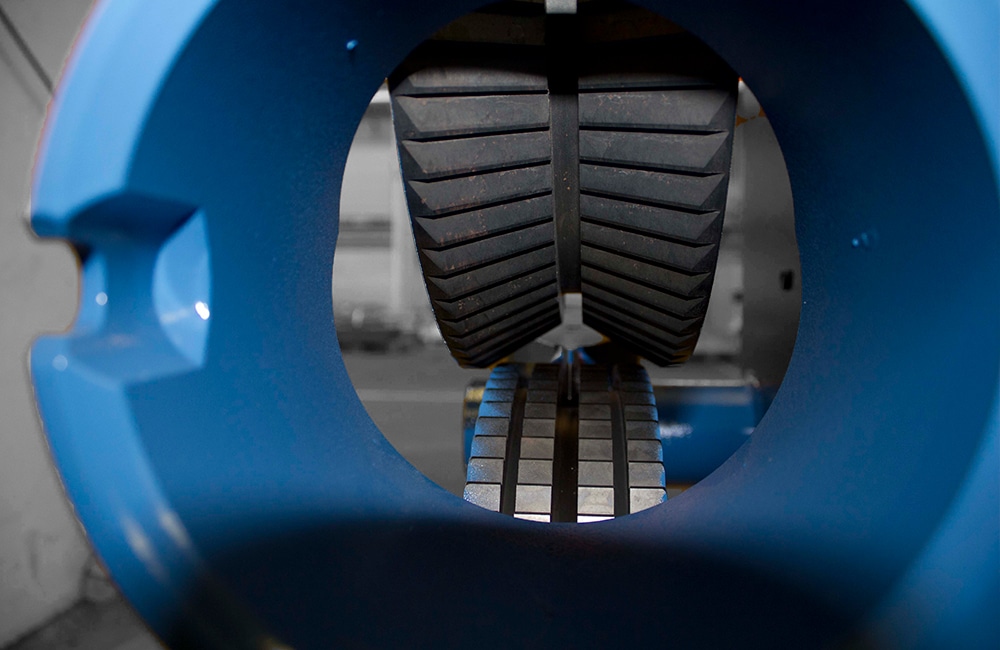

Cable Strippers

The ELDAN Cable Stripper is one of those tools that will serve you for years and years. It is a reliable cable peeler suitable for most cable types, including plastic, paper, textile, and rubber insulated cables, including butile rubber, lead armoured cables, and steel armoured cables.

The Cable Stripper features an adjustable knife for different isolation thicknesses and interchangeable input bushes for various cable sizes. It also has a fully locked guard system. Depending on the required cable diameter, the Cable Stripper is available in different sizes.

The Cable Strippers are suitable for

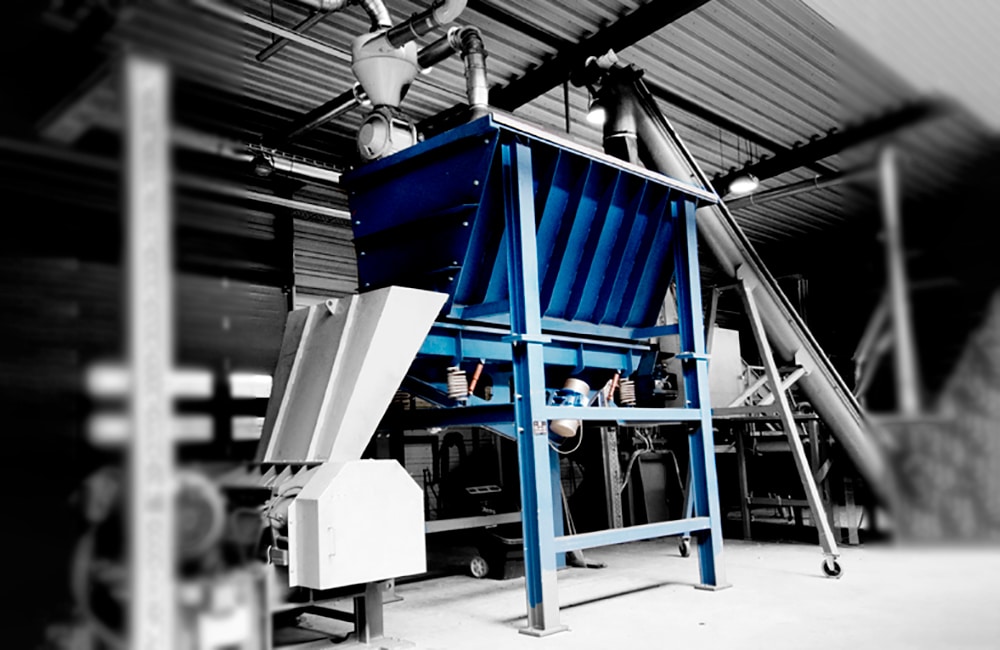

Filter Systems

To ensure a good separation and a dust-free working environment, a filter system is paramount. The filter systems delivered by ELDAN can either be complete jet-air filter systems including all necessary parts for aspiration and automatic cleaning of filter bags and guaranteed emission levels withing legal limits or simple filter systems with manual cleaning of filter bags for smaller plants with less dusty materials.

The Filter Systems are suitable for

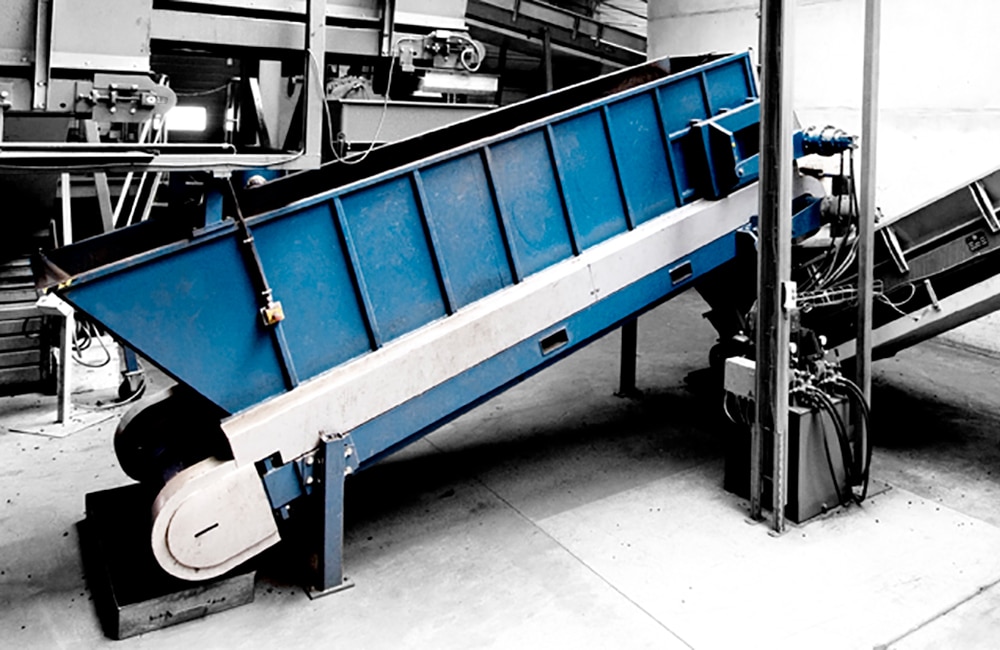

Silos

To ensure optimum flow, feeding, and intermediate storage, various silos are available. Depending on the material, capacity, and need for automation, our silo range include both open and closed silos, for feeding with belt conveyors, screw conveyors, and pneumatic material transports, with volumes ranging from 0,2 m3 to 53 m3. Since we specialise in complete recycling solutions, we will help you find the best solution for your needs.

The Silos are suitable for

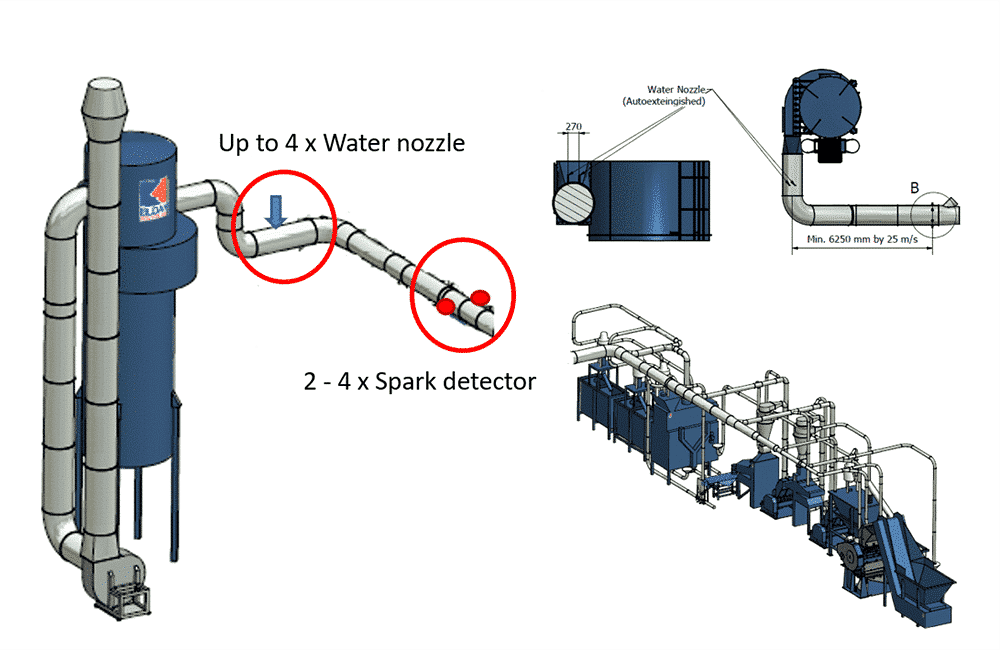

Spark Detection System

When processing flammable materials like tyres, the risk of fire will always be present – especially in high speed machines. To help prevent sparks from causing fires, ELDAN offers a specialized Spark Detection System for the Multi Purpose Raspers and Filter Systems. The spark detection system is not and cannot replace a full fire extinguishing system but serves as a compliment to avoid fires in the machines.

All depending on the setting of the sensitivity for the Spark Detection Centrals, the plant can be brought to an immediate stop or to alert mode, where water is dosed in a pre-set interval of 5 seconds. If no further sparks are detected within this interval, production will continue, but if further sparks are detected, the plant will stop entirely.

The Spark Detection System is suitable for

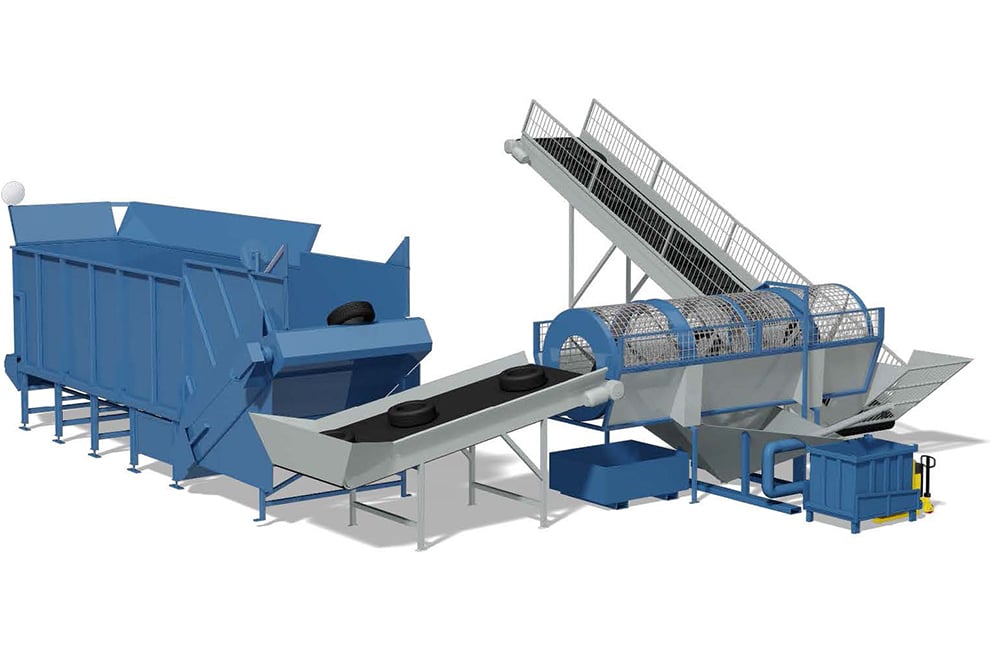

Tyre Cleaning and Washing System

Tyres can be very dirty and full of sand, snow, water, stones, and other foreign objects after storage, that can cause additional wear on knives and machines. To help prevent this, ELDAN has developed a tyre cleaning system to make sure most is removed before entering the Super Chopper.

The system consists mainly of two parts: dry cleaning of the tyres in the ELDAN Tyre Cleaner (TT6000) and washing in the tyre washing unit. During the dry cleaning, dirt and foreign objects are removed with a tumbling motion, while the following wash removes stuck material like mud and oil.

The ELDAN Tyre Cleaning and Washing System is easy to integrate into an existing tyre recycling plant and can be fed by a tyre feeder for an automatic process.

The Tyre Cleaning and Washing System is suitable for

Recycling Equipment